How To Remove A Stripped Screw

There are several ways to remove stripped screws. I'm going to show how to remove them using friction. This method works well if the screw head is at least a little bit raised off the work piece. This allows friction to be applied which "grabs" the screw and allows you to remove it.

To remove a stripped screw you place two wooden blocks on both sides of the screw, apply clamping force, and then remove the screw. The picture below shows a screw to be removed.

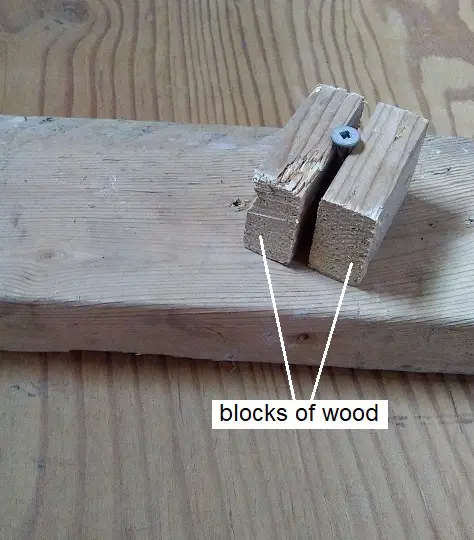

The picture below shows two blocks of wood placed on both sides of the screw.

The picture below shows a clamp placed on the two blocks of wood.

You then apply clamping force to the wooden blocks and then turn the clamp assembly in the direction that will remove the screw. If you have tightened the clamps enough the screw will turn with the assembly and the screw will be removed. If not, this means that the friction force between the blocks and the screw is not high enough, which means you have to tighten the clamps more.

In the above example the screw was raised a significant amount which allows the wooden blocks a lot of area to press against the screw shaft and create the necessary friction force. If the screw is inserted deeper into the work piece you can still use this method. The picture below shows an example of a screw raised 1/4 inch above the work piece.

The video below shows the removal of this screw using the friction method.

The method shown above also works for screws with the head broken off. The most important thing is to have enough length of screw shaft to apply the friction force so that the screw can be rotated and removed. The video below shows the removal of such a screw using the friction method. Instead of wooden blocks I used two short pieces of metal flat bars which I had lying around. Metal flat bars work better when the length of screw shaft sticking out of the work piece is short. Note that the holes in the metal flat bars I used aren't necessary and were put there for their previous use.

If a screw is all the way in the methods shown above cannot be applied, and other methods must be used. The video below shows different methods to remove a stripped screw that is all the way in.

If you have a screw that is all the way in and the head is broken off then there's likely nothing you can do except just leave the screw there. If the work piece connects to another piece and you want to separate them, you can insert a metal hacksaw blade in between the two joined pieces in order to cut through the screw shaft, which then allows you to separate the two pieces.

Return to Miscellaneous Physics page

Return to Real World Physics Problems home page

Free Newsletter

Subscribe to my free newsletter below. In it I explore physics ideas that seem like science fiction but could become reality in the distant future. I develop these ideas with the help of AI. I will send it out a few times a month.